Luxury Mechanical Watches

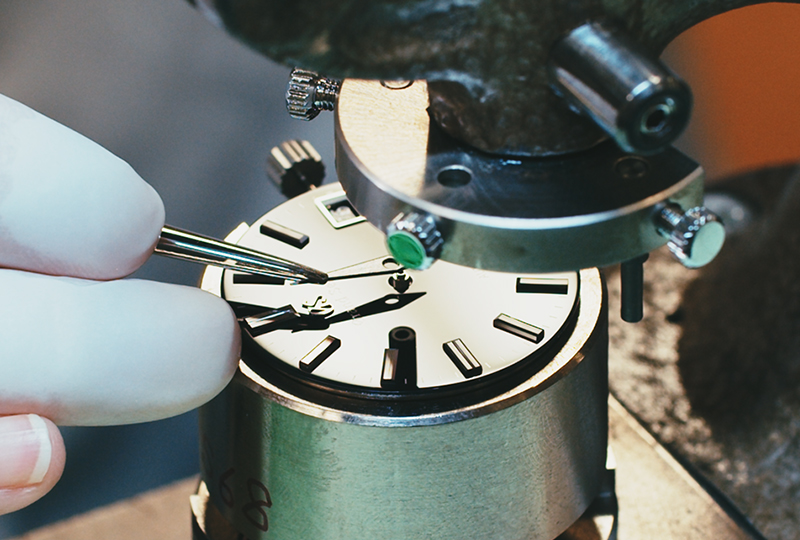

At the manufacturing site of our luxury mechanical watches, beginning with dies and jigs, we carefully manufacture very precise parts one by one. Through utilization of both the latest technology such as NC automatic lathes and MEMS (micro-electro-mechanical systems) and past equipment such as the balance staff polishing machinery inherited from the beginning (the Kameido factory era), after undergoing many other work processes and strict inspections, our luxury mechanical watches are born. Many carefully processed parts are finished by hand. The highlight of the assembly process is the mounting of the balance wheel, which is the lifeforce of a mechanical watch. At that moment, the movement begins ticking as if life had been breathed into it.

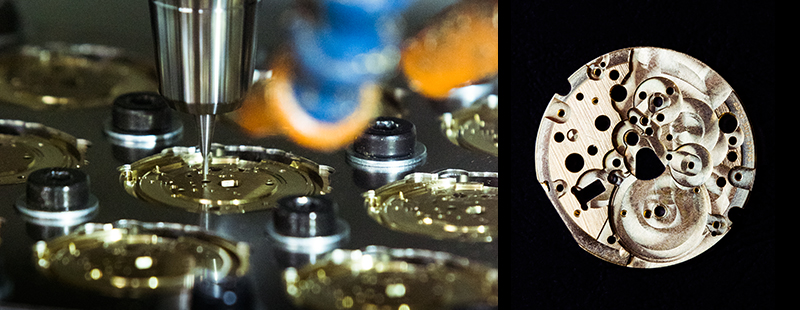

Assembly of mechanical movements

Assembly of mechanical movements

Micro Electro Mechanical Systems

Micro Electro Mechanical Systems

Main plate and bridge process

Main plate and bridge process

Parts assembly

Parts assembly

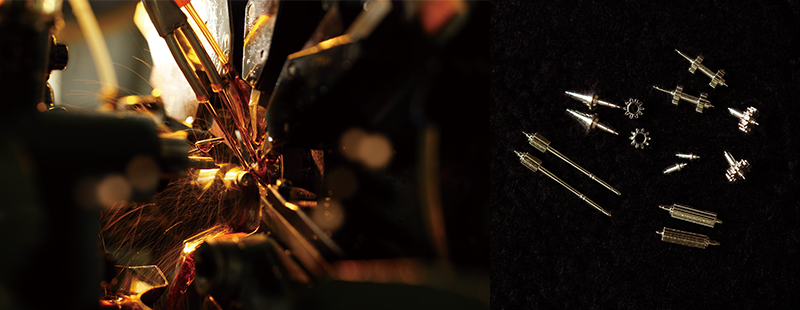

NC automatic lathe process

NC automatic lathe process

Our luxury mechanical watches are assembled by highly-skilled craftsmen and their accuracy is certified through the extremely strict standard inspections as represented by the Grand Seiko standard inspection. We carry out manufacturing with pride as a company that creates all elements of our watches ourselves.

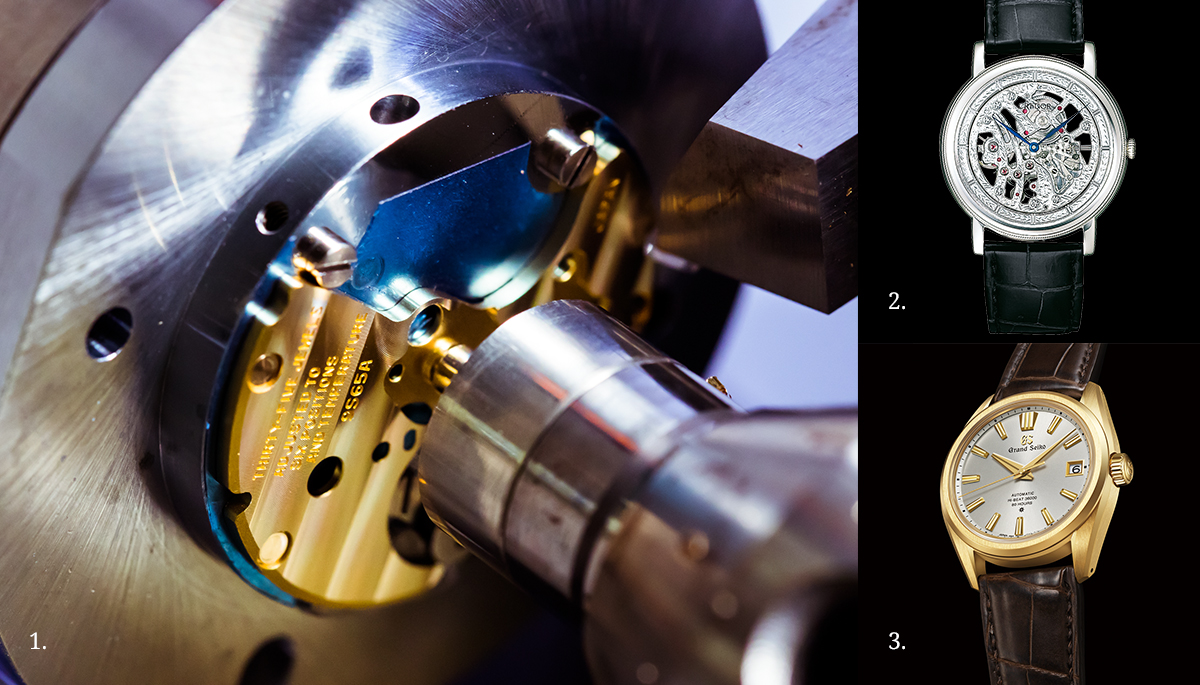

1.Decorative process 2.CREDOR 3.Grand Seiko

1.Decorative process 2.CREDOR 3.Grand Seiko

Grand Seiko standard inspection

Grand Seiko standard inspection

External parts assembly

External parts assembly

Band attachment and shipping

Band attachment and shipping